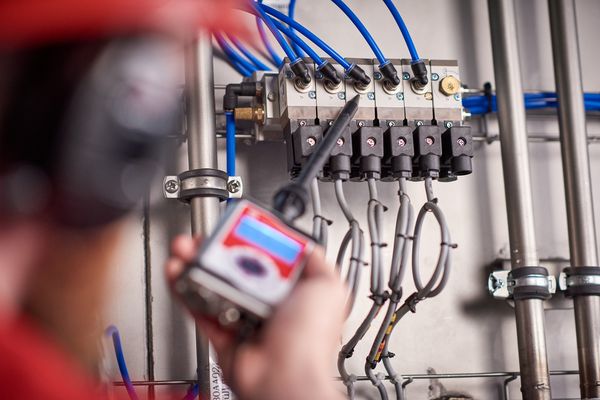

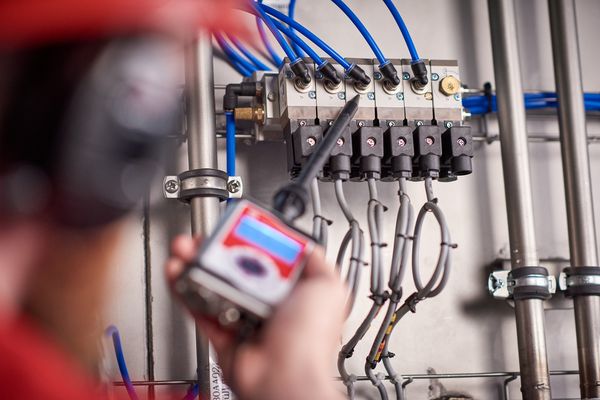

SONAPHONE® Pocket

Compact Ultrasonic Testing Device for Preventive Maintenance

Numerous preventive maintenance tasks can be handled quickly and efficiently with the SONAPHONEPocket. Lower your energy costs and increase your operational safety with the most compact testing device of the SONAPHONE series. The device is perfectly suited for:

- Leak detection on compressed air systems

- Condition monitoring

- Detection of partial discharges

- Tightness testing

Advantages

The SONAPHONE Pocket is used for

Applications

- leak detection with compressed air, gas and vacuum systems,

- wear control on rotating machines,

- providing evidence of partial electrical discharges where there is insulation damage and

- tightness testing of unpressurized systems.

With the SONAPHONE Pocket you identify problems even before they arise and create value at all levels of your company. Just by detecting and eliminating leaks you can reduce the energy costs for your compressed air system up to 30 percent. This also has positive effects on your operational safety and system productivity through early warning of bearing failure and evidence of partial electrical discharges.

With the SONAPHONE Pocket you identify problems even before they arise and create value at all levels of your company. Just by detecting and eliminating leaks you can reduce the energy costs for your compressed air system up to 30 percent. This also has positive effects on your operational safety and system productivity through early warning of bearing failure and evidence of partial electrical discharges.

With the SONAPHONE Pocket you identify problems even before they arise and create value at all levels of your company. Just by detecting and eliminating leaks you can reduce the energy costs for your compressed air system up to 30 percent. This also has positive effects on your operational safety and system productivity through early warning of bearing failure and evidence of partial electrical discharges.

You do not need much time or expensive training in order to perform the test procedure. The testing device makes the ultrasonic signals audible and shows them on a digital display at the same time. The SONAPHONE Pocket – easy to handle and very effective.