Electric grease pump for pail, 1/4 or 1/1-drum

| Grease pressure: | 35 MPa/5 075 psi |

| Output: | 150 g/min at 1 400 rpm |

| Outlet connection: | Utv. ISO-G1/4 |

| Electric motor: | 3-phase 230/400 V 50 Hz 0,37 kW 1 400 rpm IP 55 |

Description

This high pressure piston pump is powered by an electric motor via a worm gear and is suitable for applications where compressed air is not available. The pump operates automatically by means of a a pressure switch in the outlet, switching on or off the power according to the pressure limits set. (Please note that this function is only available if you have the control unit.)

TECHNICAL DESCRIPTION

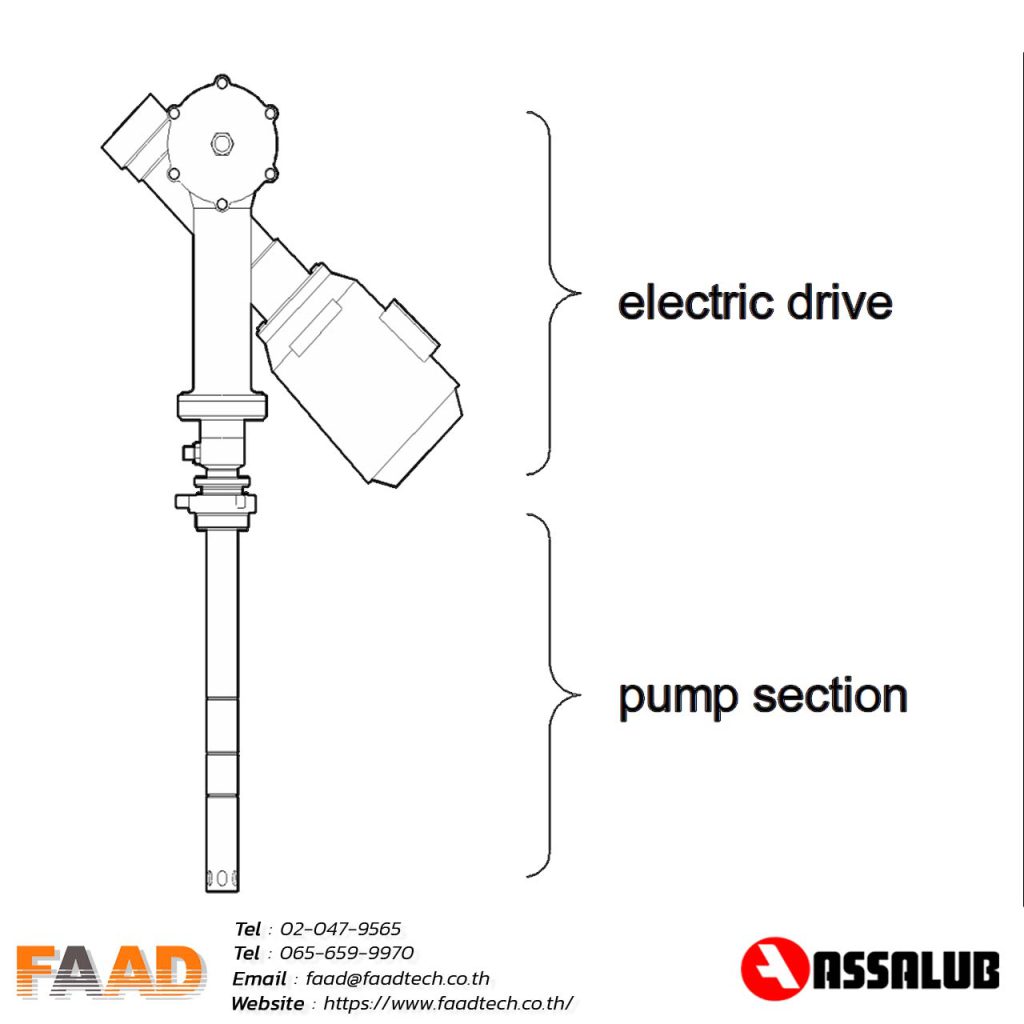

Components of electric grease pump

The pump part consists of a piston pump. The piston and cylinder are made of hardened steel and are meshed together. The pump needs to add a pressure sensor and a control device to start and stop automatically. The controller stops the motor when a preset voltage is generated. and restarts when the pressure drops. For this reason, a control device is required for use with grease guns. The cut-off voltage is set by the pressure sensor. The control device also has an automatic circuit breaker to protect the motor. If there is a problem It can be reset by pressing the reset button electric drive.

TECHNICAL DESCRIPTION

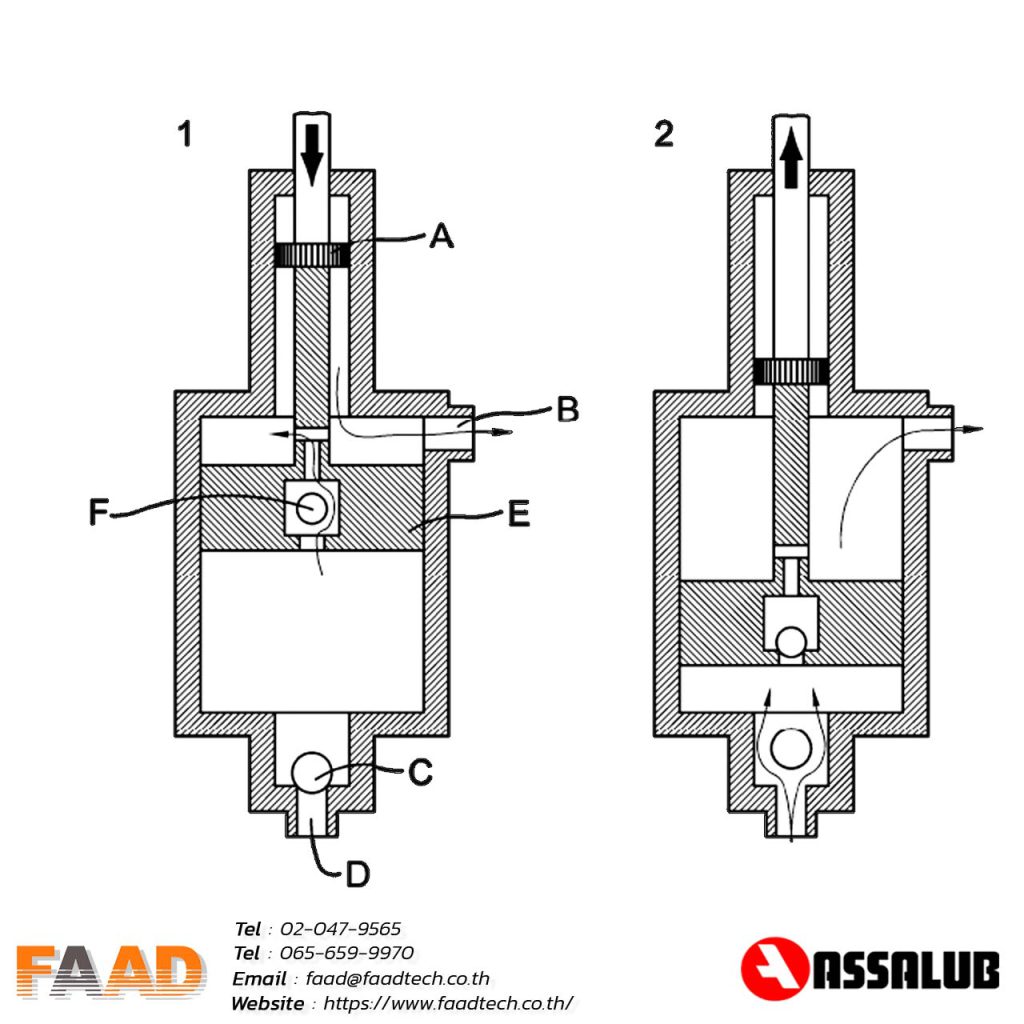

Piston descending as shown in Figure 1.

Piston A pushes the liquid out through the outlet B. Ball C prevents the liquid from being pushed out through the inlet D. At the same time, The fluid under piston E is pushed through ball F into the space above piston E.

Piston ascending as in Figure 2

Ball F blocks its way through the piston. Since the area of piston E is greater than that of piston A, the fluid above piston E is pushed out through outlet B. New fluid enters under piston E when ball C opens inlet D.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.