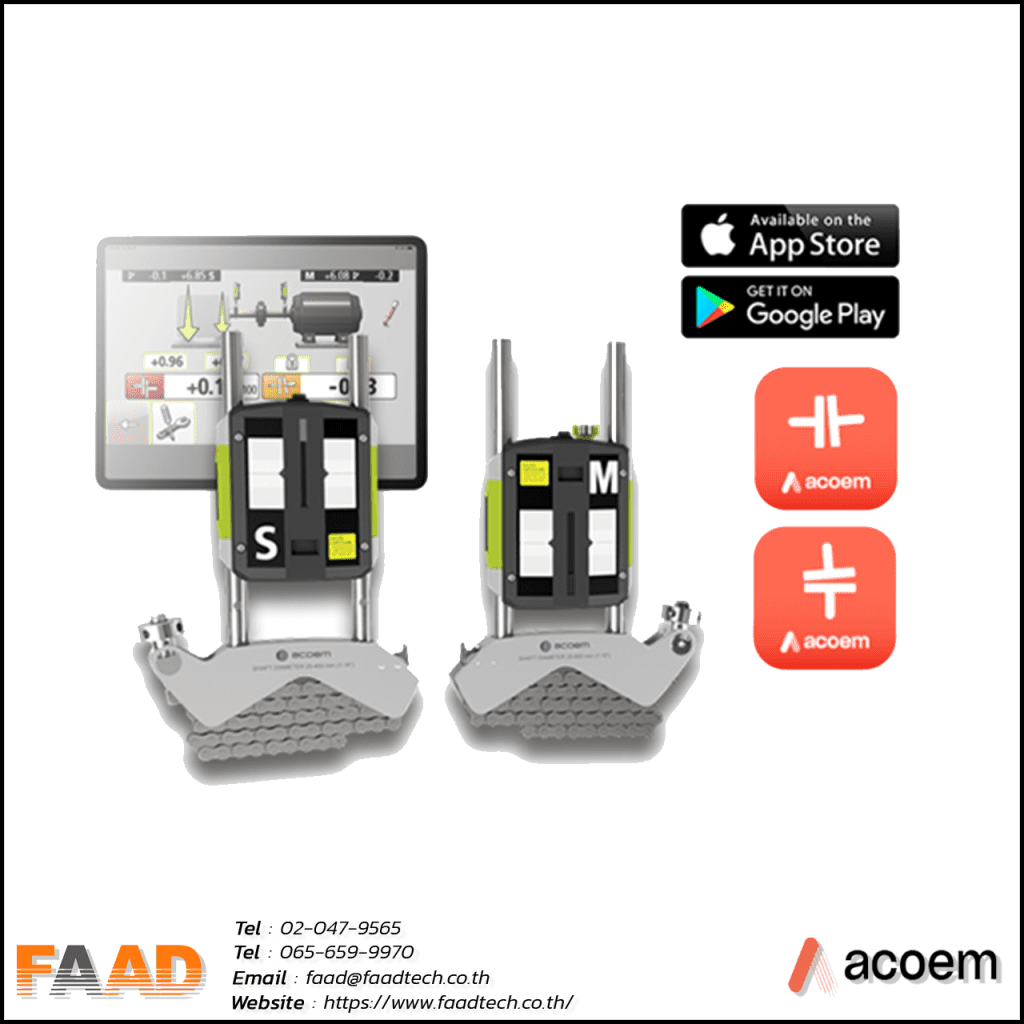

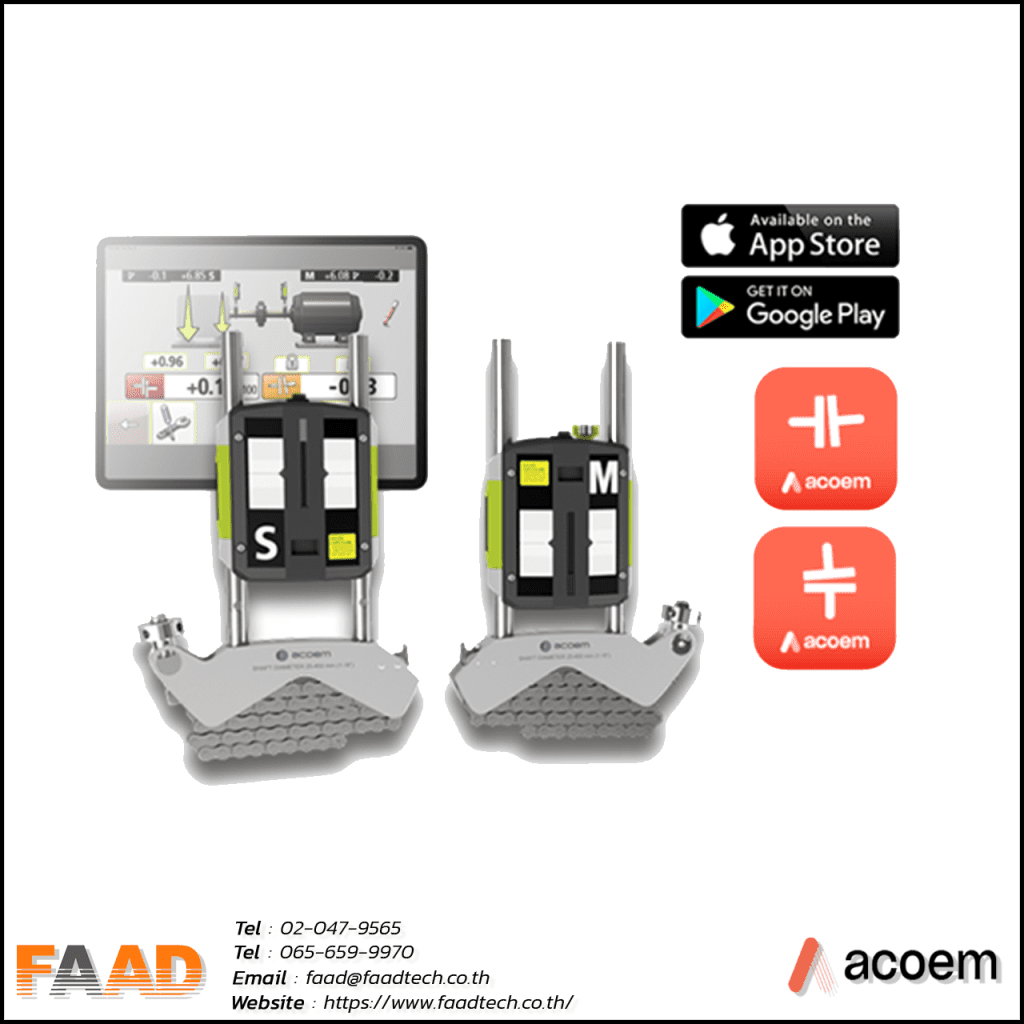

Acoem AT-200

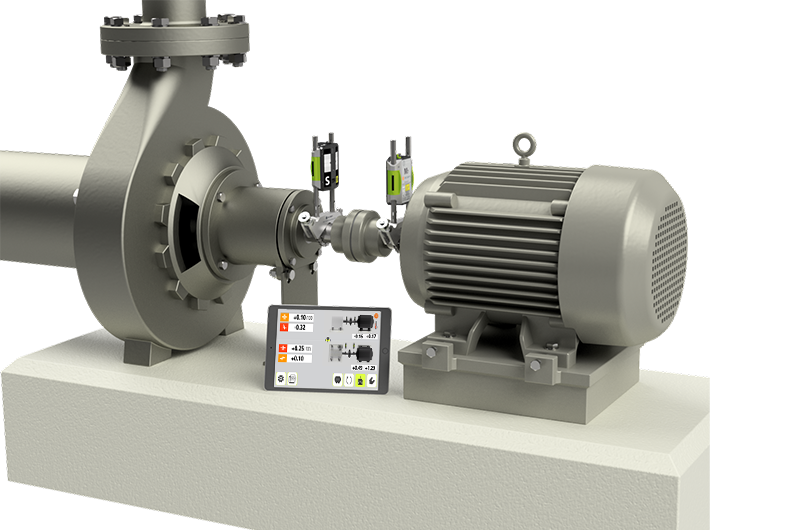

The new generation of horizontal & vertical laser shaft alignment solution. Providing unparalleled measurement performance and fast, precision alignment, the AT-200 leverages technology to enhance your user experience and helps you extend your critical machinery’s lifespan.

Shaft alignment will not be difficult anymore!!

with high accuracy with modern technology

Solve problems quickly Keep up with the situation in just 3 easy steps

- Easy to install with the Guide U function to guide you through step-by-step operations, even non-experts can use it easily.

- Level both vertically and horizontally with just one measurement. Quick results by Vertizontal function

- Instant ready-to-use reports in full-detailed PDF format. which saves a lot of time.

Smart alignment tool

So much more than an alignment tool, the AT-200 Toolbox combines CCD technology smart sensors with full connectivity via our shaft alignment apps and a cloud-based platform to give you the power to make informed decisions and take corrective maintenance action immediately – straight from your tablet or smartphone.

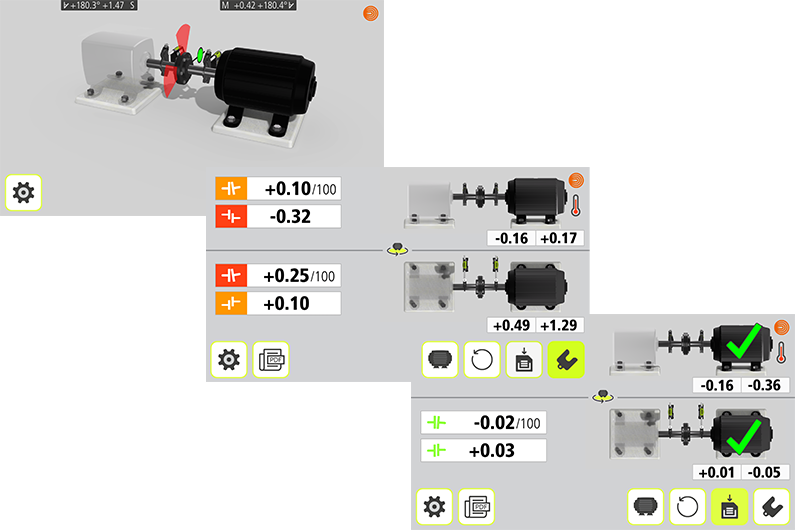

Intuitive GuideU™ interface

Our patented, customisable, icon-driven and color-coded display system makes measuring, aligning, documenting and reporting on each job simple. It minimises the risk of error by guiding you through the process using visual, logical and easy-to-follow steps to deliver precise measurement and correction values. Lighting and graphic reflections have been optimised for use on mobile devices in industrial environments.

TrueLive™…. a game changer for shaft alignment

An industry-first technology, TrueLive™ functionality ensures that you always know your machine’s exact position. Its two compact smart sensors feature laser beams and inclinometers which monitor both shaft positions simultaneously. Even if you move the machine’s position out of detector range or interrupt the laser beam, the smart sensors will resume with an updated machine position and always deliver live values, saving you considerable time when aligning your machinery.

The best accuracy for industrial applications

The supervisor CCD technology of AT-200 sensors makes them highly tolerant of detrimental external factors, such as vibration and ambient light and provides unrivalled digital filtering capabilities. Simply switch ON the smart Alignment Intelligence filter to automatically adjust sampling time and provide intelligent screen filtering in live alignment mode with outstanding results. The line laser virtually eliminates rough alignment, delivering the most accurate and precise measurement values throughout the alignment process.

Add the power of thermography

If your machine is misaligned, it will create extra heat. Integrating thermography with the AT-200 gives you added insight into your alignment process by allowing you to capture images that detect those changes in heat levels around your machinery’s coupling.

Connect the optional FLIR One Pro thermography camera to your machinery to take pre-and-post alignment thermographic images remotely. Then seamlessly integrate the required images into your automatically generated AT-200 PDF report* to provide visual proof of the successful alignment for a smooth user experience and greater reliability in complex alignment situations.

*Available on Android devices

Grow your maintenance capabilities

The AT-200 is just one solution in Acoem’s Augmented Mechanics Ecosystem – the first truly flexible and scalable solution for combining different technologies on the same mobile platform to deliver reliable and precise proactive and predictive maintenance for industrial machinery. Continually add tools or upgrade as new technologies become available, or as your specific needs change over time.

In addition to the Horizontal and Vertical shaft alignment apps, the Ecosystem currently features:

The Pre-alignment app, designed to remove the complexity of your laser alignment process, making it faster and more reliable (works with the Acoem wireless Run-out probe)

The Bearing Defender app, which provides quick first-level information on bearing health based on vibration readings in a matter of seconds (works with an Acoem VT-300 wireless vibration sensor)

The Machine Defender app, which provides full rotating machinery with AI-powered vibration diagnostics instantly in the field (works with an Acoem VT-300 wireless vibration sensor)

The FLIR One thermography app, enabling quick and easy thermography controls from a mobile device (works with FLIR One Pro camera)