Steel industry Cold rolled steel

Cold rolled steel is gray-white coiled steel. Formed from steel coils going through a cold rolling process. Then rolled to reduce thickness at normal temperature. It is called white steel or Cold-Rolled products.

Customer Requirement

The customer’s need is to view the vibration signals of each Mill Stand in real time to prevent machine break-down problems.

Solution

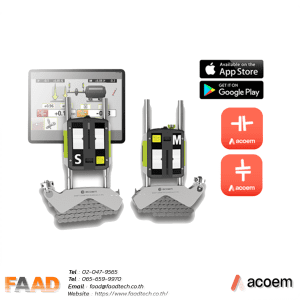

- Realtime collection and low speed machines suitable for Wireless Vibration MVX

- Use the Function Shock Finder index (SFx) and Bearing Defect (DEF) on the Nesti 4 wireless analyzer to envelope the vibration signals to look at specific bearing problems.

- Use Acurrex AI to help analyze problems

- Machine Learning to perform additional analysis to suit the machine.

Result

Customers can detect problems related to vibration and can collect vibration values that are difficult for portable devices to collect. There is also AI that helps with work and reduces the process of measuring and analyzing vibration values by up to 80%.

Conclusion

Customers can use Product MVX together with the Nesti4 program and use the Function Shock Finder Index and Bearing Defect to prevent damage caused by vibration.

Project Details

Customers

เหล็กแผ่นรีดเย็น

Location:

Thailand

Category

Steel production & factory

Project Manager

Website

https://www.faadtech.co.th/

Correct problem solving

The MVX system can be packaged in an easily transportable box. Conveniently transportable on-site. BNC for 8, 16, 24 or 32 channels to meet the needs of on-site inspection applications:

- Rugged IP54 grade with in-box fan for cooling and UPS power supply.

- Accommodates a 15-inch laptop PC.

- Dimensions: 560 x 465 x 265 mm (22.0 x 18.3 x 10.4 inches)

- Weight: 16 kg (30 lbs)

The inspection case can be closed even with a computer inside. Can be used for a long time without problems During field use One week One month | Ideal for inspecting the most complex machines. best signal Ability to process for the purpose of solving problems as directly as possible

Steel industry : Sahaviriya Steel Industries PLC

hot rolling mill Used to reduce the size of steel with temperatures over 1,000 degrees. Hot-rolled steel sheets can be used for many types of applications. For example, using it as structural steel of various shapes such as angle steel, pipe steel, gutter steel, processed angle steel.

Customer Requirement

The customer’s main need is to look at the bearing impact signals of each ball. To prevent damage to the Bearing and want to collect Vibration values in Realtime and be able to notify Alarm via Line and Mail.

Solution

- Realtime collection and low speed machines suitable for Wireless Vibration MVX

- Use the Function Shock Finder index (SFx) and Bearing Defect (DEF) on the Nesti 4 wireless analyzer to envelope the vibration signals to look at specific bearing problems.

- Use Acurrex AI to help analyze problems

- Machine Learning to perform additional analysis to suit the machine.

Result

Customers can detect problems related to vibration and can collect vibration values that are difficult for portable devices to collect. There is also AI that helps with work and reduces the process of measuring and analyzing vibration values by up to 80%.

Conclusion

Customers can use Product MVX together with the Nesti4 program and use the Function Shock Finder Index and Bearing Defect to prevent damage caused by vibration.

Project Details

Customers

Sahaviriya Steel Industries PLC

Location:

Thailand

Category

Steel production & factory

Project Manager

Website

https://www.faadtech.co.th/

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/dASH456-2-600x600.jpg)