What is Partial Discharge ?

PARTIAL DISCHARGE ?

Partial Discharge is an electric charge that destroys the insulation. Occur both in the insulator and outside the insulator by Partial Discharge that occurs in the insulator It is the result of the charge flowing through a small gap. in the insulation and damage These gaps will withstand less voltage than the insulation around them. Damage that may occur is a Breakdown, a fire. and damage the system within the organization

TYPE : Partial discharge

- Corona Discharge: This common form of partial discharge occurs when discharge is directly into the air emanating from the sharp surface of the conductor. (This is what causes the sound and radio frequency emissions.) From a damage or safety perspective, corona isn’t normally concerning.

- Arcing Discharge: Arcing discharge is a prolonged electrical discharge produced by the electrical breakdown of a gas. Plasma is produced when current flows through air, or any other normally non-conductive medium.

- Surface Discharge: When discharge travels along the surface of insulation, this is called surface discharge—or surface tracking. It can be one of the most destructive types of partial discharge. Contamination and weather of the insulator surface are the two most common causes of surface discharge. In medium- and high-voltage equipment, this type of discharge occurs when insulation breaks down, usually due to high humidity or poor maintenance. Moisture intrusion is also a common cause of surface discharge.

- Void (internal) Discharge: This is most often caused by a defect in the solid insulation of cables, bushings, GIS junction insulation, and such. Void discharge is highly destructive to insulation and will typically continue to expand until they cause complete failure.

Partial discharge detection

Surface discharge and Void dischard should be the focus of investigation. And hurry to solve work related to high voltage industry, system technicians, power transmission system engineers. Original Equipment Manufacturers (OEMs), Electrical Engineers In many cases, detecting and correcting partial discharges is a safety priority. In addition to personal safety, it can also cause other damage such as: Machine Breakdown, Fire, Insulator Deterioration, Grid Overload.

These problems can be avoided if detected early. before serious damage occurs. Nowadays, there are several ways to detect partial dischard. They can be detected using ultrasound, radiofrequency (RF) and ultraviolet radiation. and many more ways to use and training in order to use it properly and most efficient

Tools to assist in the detection of partial discharge

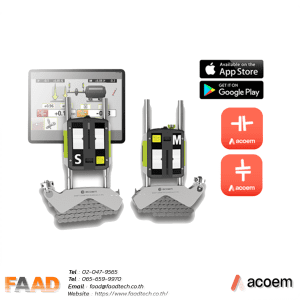

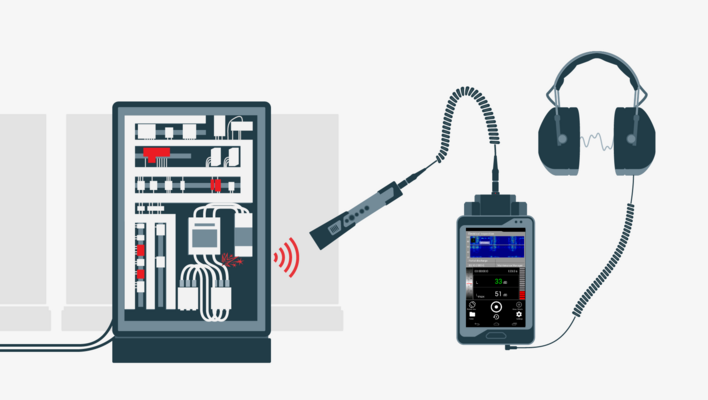

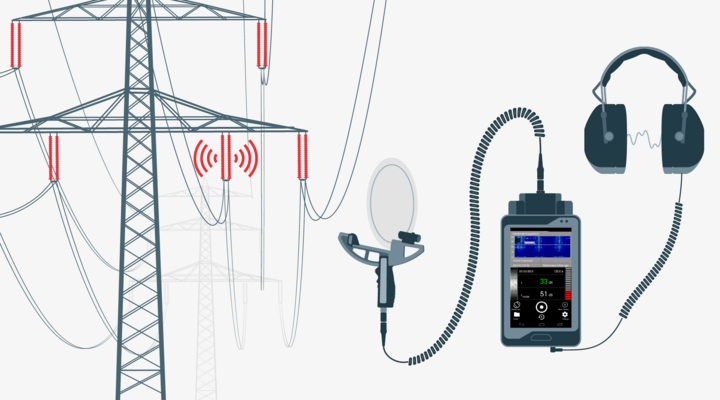

In conjunction with the SONAPHONE ultrasonic testing equipment, the SONOSPOT parabolic dish is used to detect hard-to-reach or distant damage. such as on power transmission and distribution lines. The high sensitivity and precise orientation of the sensor enable the detection of electrical partial discharges and insulation damage such as medium voltage electrical equipment (Medium-Voltage) or switchgear Increased tendency of partial discharge can lead to widespread damage in the insulators.

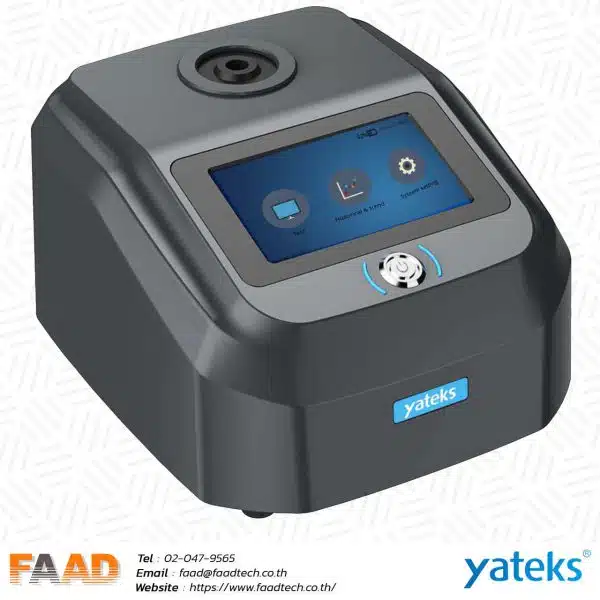

Regular inspections of electrical equipment are essential for preventive maintenance. SONAPHONE devices can be used to detect and classify the severity of corona, tracking and arcing problems. For both high, medium and low voltage equipment to monitor open or closed electrical systems. To inspect switching cabinets, control boxes, relays, transformers, insulators, etc.

Leak Detector Acoustic Imager | Cry Sound CRY2624 is an explosion-proof instrument suitable for petrochemical and heavy-duty industries.

Analytics and Reports

Template-based processing and recording of data, waveforms,spectra,spectrograms is supported by CRYSOUND report analysis tool software, generating ISO 50001 compliant, editable protocols in Excel format.

PD Detection & PD Type Identification

Partial discharges can be detected before more serious faults would occur, even before a thermal camera would detect them.

SONAPHONE® Pocket

SONAPHONE® T & SONOSPHERE

SONAPHONE Pocket

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/ASH456-1-600x600.jpg.webp)