What is Lubrication ?

Lubrication

Lubrication is the process of reducing friction. To understand about lubrication. So in the first part. We will get to know Forms of pre-lubrication, causes and effects of friction. And in the next part will be about tools used in work in various industries.

Friction arises from the friction between The contact surface therefore needs to be lubricated. for the purpose in reducing friction The effect of reducing friction will be wear and tear and heat generated by friction to lower the temperature

Types of Lubrication

When considering the motion between contact surfaces or the slipping of two pieces of metal We will find that there are many mechanisms for lubrication, including

- Hydrodynamic lubrication or thick film lubrication

- Hydrostatic lubrication

- Boundary lubrication or thin film lubrication

- Solid Film lubrication

Hydrodynamic lubrication or thick film Lubrication

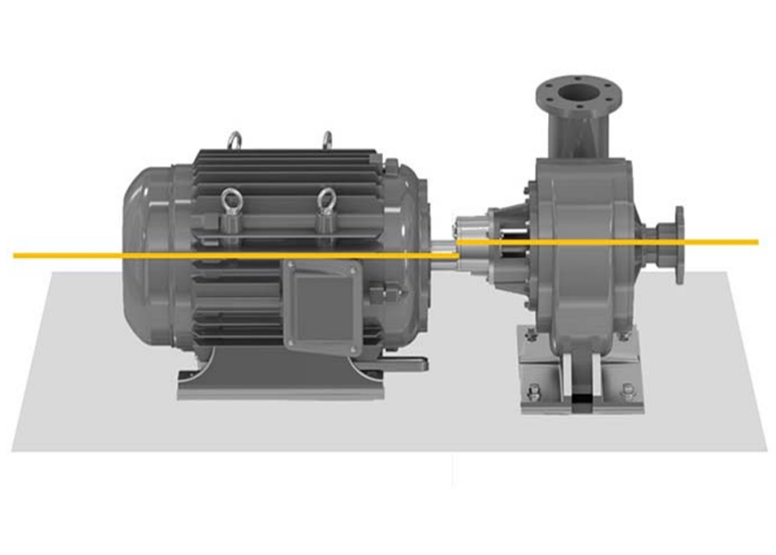

The principle of Hydrodynamic lubrication is when the shaft (Journal) rotates in the bearing at high speed. And there is enough lubricant inside the bearing. The rotating force of the shaft creates an oil wedge between the rotating contact surface and the stationary part. As the speed increases, the pressure of the oil wedge increases. until the oil film is strong enough to support the load where the metal surfaces are not in direct contact

Hydrostatic lubrication

Hydrostatic lubrication is hydrostatic lubrication, meaning that the right amount of lubricant is compressed. (which may be oil, water or air) into the bearing at high pressure only enough to separate the contact surface It was found that the contact surface separation It is similar to hydrodynamic lubrication.

or lubrication with an excess amount of lubricant between the bearing surface and the shaft That will make the metal surfaces not touch each other because the shaft moves at high speed causing the lubricant to be drawn through the wedge-shaped hole to cause pressure to build up within the lubricant layer. from such pressure As a result, the metal parts do not touch each other.

Boundary Lubrication

Boundary lubrication is a lubrication that Occasional contact with bearing surfaces may occur in the case of hydrodynamic lubrication where speed of the shaft (journal) is reduced or if the amount of casting not slippery or if the temperature of the lubricant This may be due to a decrease in viscosity resulting in temporary contact between contact surfaces.

This type of lubrication generally occurs when

• shaft that restarts work .

• Rotational speed is not very high.

• Very high working load on shaft

• Lack of oil viscosity.

Solid film Lubrication

Solid film lubrication may also be called solid lubrication. to be used in cases where lubrication is required in high temperature or hard work at high rotation Lubrication using liquid lubricants may not be effective. Solid substances used as lubricants include Molybdenum, Graphite coated on the surface of the Bearing for slow wear rate.

Tools used in grease work

ปืนอัดจารบี (Lubricators/Grease Guns)

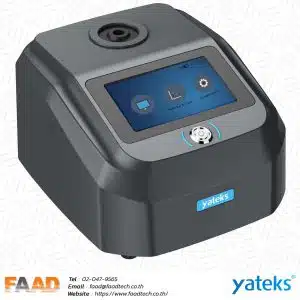

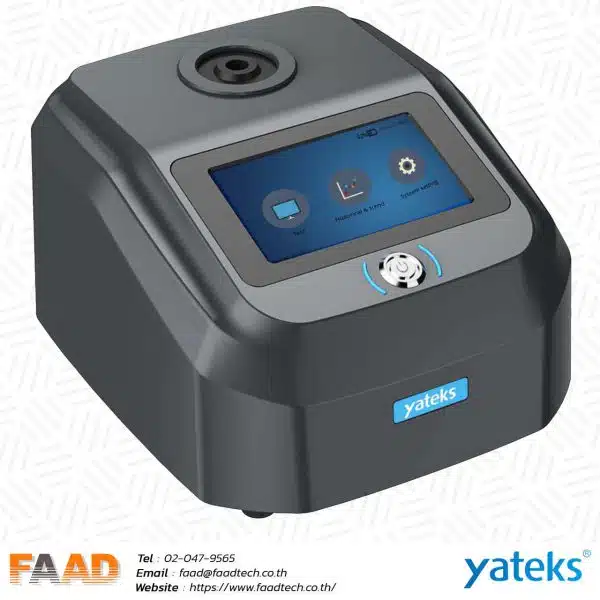

LubeRight

LubeRight is a tool to assist in checking grease content. Check the grease filling interval. control the operation through the computer system Collect data by dividing into Name, Lubricant volume to be dispensed, Lubrication Frequency, Lubrication Point

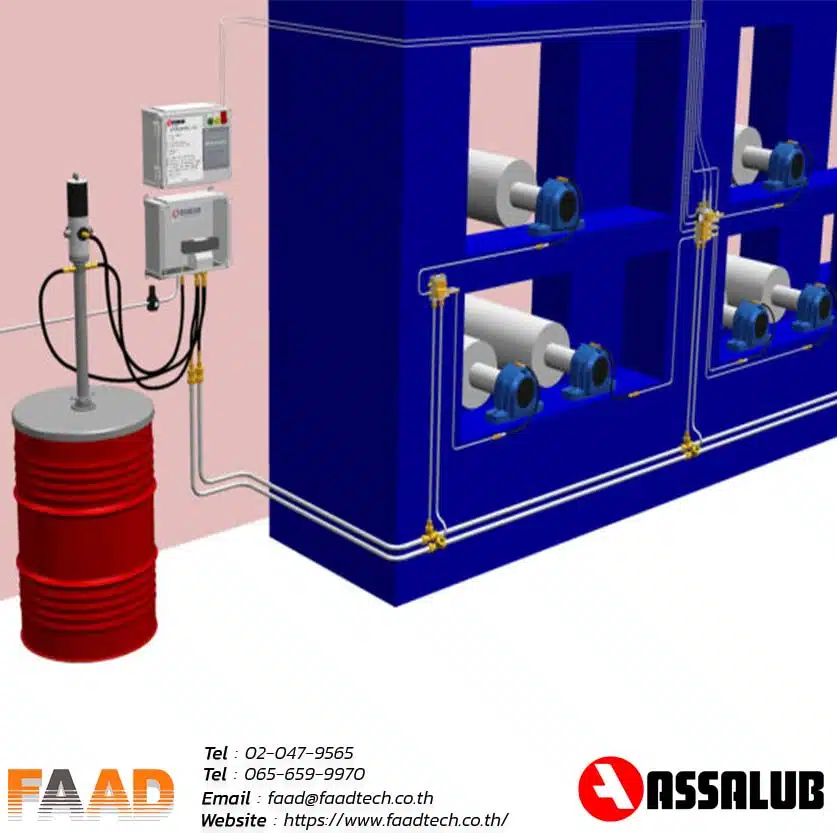

SINGLE-LINE LUBRICATION SYSTEMS

Automatic lubrication System

A lubrication system that works easily, conveniently, quickly, and can check the amount of grease. and cost-effective for automatic lubrication systems It consists of a dosing pump, a control unit and a device for distributing grease. This is because the grease is discharged from the drum directly to the grease hose. Your system must be free from contaminants.

DUAL-LINE LUBRICATION SYSTEMS

Automatic lubrication System

Assalub’s dual-line labeling system for hard-to-reach access points. The dosing kit is manufactured from registered steel. A dual-wire system for more than 1,000 Assalub measurement points and is controlled either by a control unit for one or more channels or by a machine control unit.

MULTI-LINE LUBRICATION SYSTEMS

Automatic lubrication System

In light and medium-heavy industry – in contrast to heavy process industry – individual machines with a smaller number of lubrication points are used. Applications in which grease lubrication is used include for instance pellet presses, gears, stone-crushers, cement kilns, screw conveyors, travelling hoists, process filters, ship steering and lubrication of rudders shafts, cranes, rotary filters, industrial separators, etc.

Assalub builds lubrication systems for the applications mentioned above. Includes multi-line lubrication systems for grease (FLM and FEM types) and for oil (B type).

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/ASH456-1-600x600.jpg.webp)