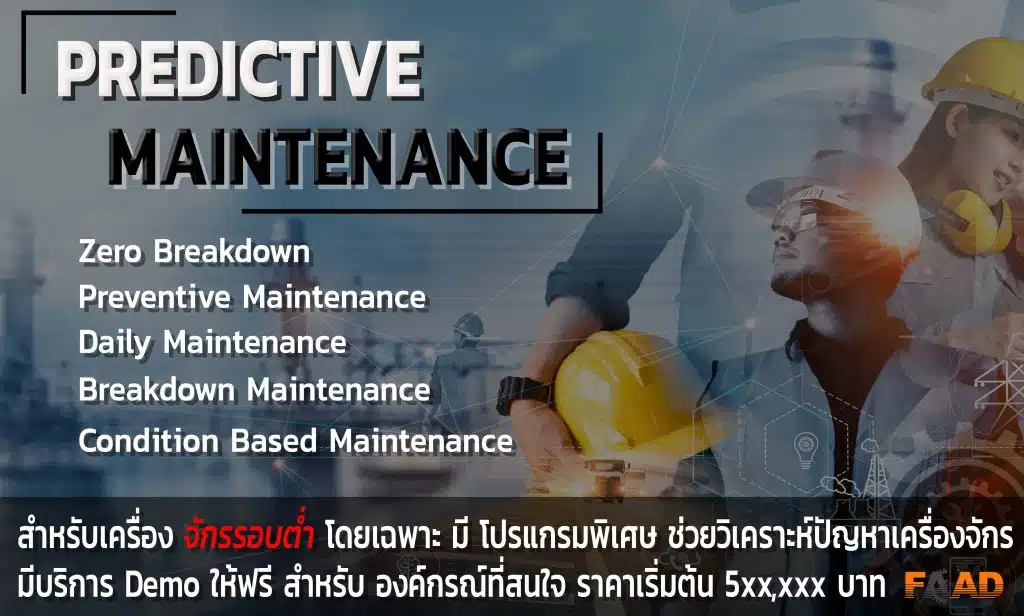

What is Predictive maintenance

Breakdown Maintenance

Maintenance after damage to the machine or the production process must be stopped. The official is called It is maintenance in response to incidents. Reactive Maintenance. This type of maintenance may use parts of the equipment until they are damaged and then replace them, or in some cases, it is repaired due to unexpected events. or not planned This type of maintenance is the easiest maintenance. Just solve immediate problems according to the situation only. This may be planned or unplanned maintenance, in contrast to preventive maintenance. Divided into main topics: Planned maintenance and Unplanned maintenance

Predictive maintenance

Predictive Maintenance or predictive maintenance system It is a prediction of damage to machinery and equipment inside the machine. Using historical data and measuring machine performance and damage through tools such as Using various analytical tools or using AI to help analyze problems To help predict the time that the machine will be damaged or deteriorated from use. And can manage the maintenance plan of the machine. before the machine will cause heavy damage May result in a Breakdown, which this system will reduce costs for business owners in emergency maintenance.

Things you should know about Maintenance is divided into two types, planned maintenance and maintenance that is not in the plan or problems before work (Unplanned Maintenance). held very different events If looking into the details, it can be divided into 3 main topics as follows.

- Machine management before installation

- Handling the machine during operation

- Management of machines after retirement

Planned Maintenance

Pre-documented and scheduled planned maintenance The purpose of planned maintenance is Reduce machine downtime by requiring rigorous planning and timelines. In the work schedule, it must be clear that Which parts will break and should be replaced periodically. such as replacing shaft bearings And which parts will be maintained at the scheduled time. through preventive maintenance

Zero Breakdown has the main prevention factors divided into 2 major topics: Autonomous Maintenance and Planned Maintenance, and the types of maintenance according to the Planned Maintenance program can be divided as follows.

PM : Preventive Maintenance : It is to maintain the machine must comply with the basic operating conditions of the machine, meaning that it must have normal operation.

DM : Daily Maintenance : Is the maintenance of the machine, also known as daily maintenance, such as lubrication, tightening, adjustment, inspection and replacement of various parts. to measure deterioration

BM : Breakdown Maintenance : It is a repair when the machine is broken. That is not planned in advance and often causes high costs.

TBM : Time Based Maintenance : It is a maintenance that is performed at scheduled intervals at regular intervals.

CBM : Condition Based Maintenance : It is a maintenance form that determines the deterioration of machine parts. using machine diagnostic techniques Then predict the trend according to the probability of deterioration.

PdM : Predictive Maintenance : It is a maintenance that uses new methods or techniques. by using various measuring tools to monitor the machine condition and use that information for maintenance planning.

Run to Failure (RTF) Is part of the Planned Maintenance method, Run to Fail is a strategy that intends to allow equipment or parts to work until they fail or become unusable. And the owner or the maintenance department is ready to fix it immediately or replace it immediately. as planned and prepared spare parts

Unplanned Maintenance

Unplanned Maintenance is corrective maintenance. that is not planned or caused by sudden events Or an event that causes parts of various equipment to be damaged to the point that it cannot continue to be used. Or it may be called the Breakdown event, stopping production unplanned by The main contingency plans are divided into two main parts:

- Reactive Maintenance Is maintenance that responds to events that occur, or called immediate maintenance according to tasks that occur during that period Or is to go into equipment maintenance after an unexpected breakdown. This type of maintenance is done for an emergency and has not been planned.

- Corrective Maintenance การบำรุงรักษาเชิงแก้ไข แIs to make machines or equipment work again after having to stop work. It is corrective maintenance, such as fixing specific problems that are critical. to make machinery back to work again

Technology for predictive maintenance

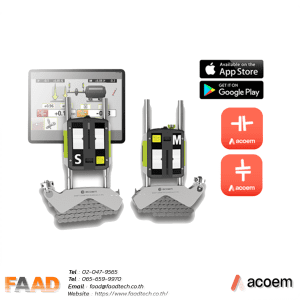

Vibration Analysis (VA)

Vibration is the oscillation or oscillation of objects around the equilibrium point, such as the swing of a pendulum. water pump vibration or the vibration of the speaker, etc., machinery or motors in all kinds of industries There will be a vibration that indicates the condition of the machine. If the measured vibration value is high It may be caused by the imbalance of the machine (Unbalance) or caused by misalignment, which will cause damage to the machine. It may cause a breakdown that directly affects the production process.

SEEMORE > VIBRATION <

how good will it be

If there is a wireless vibration meter (Wireless Vibration), vibration will automatically

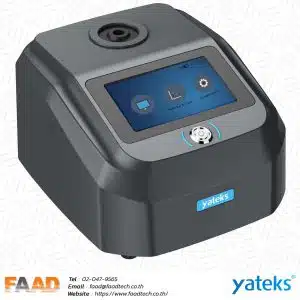

FALCON Smart Portable Vibration Analyzer

A smart tool that can help you find out the real problems of all 3-axis machines in seconds.

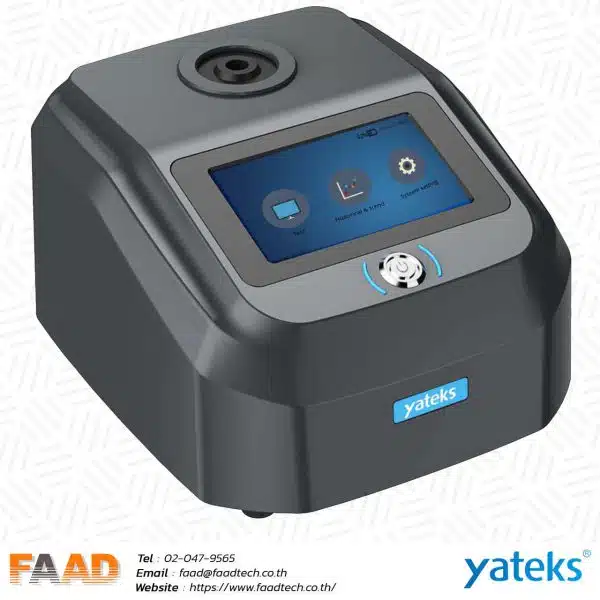

“Eagle” is a Wireless Vibration instrument used for measuring Vibration wirelessly.

and transmit data online via LAN / WiFi / 4G

Therefore, we no longer need to go to the site manually, just have a computer connected to the network, able to monitor and analyze the condition of the machine from anywhere. Suitable for areas that are difficult to reach and are highly dangerous.

Reduce the risk of workers inspecting machines. What’s more, Eagle can also store the value quite often, 1 time per hour. The battery can be used for up to 5 years and can also set the vibration alarm value. When the machine has a problem, the report can be sent to Email immediately.

Online Vibration Machine Analysis System

Measurement of machine vibration is very important. because it allows us to know the problems of the current machine before it breaks down, which can be divided into 3 types of vibration measurement systems, mainly according to the frequency of collecting values as follows:

“Offline” rarely collects values maybe once a month once a week by allowing people to hold a vibration meter to measure at the site Suitable for innocuous and easily accessible spots.

“Semi-Online” collects quite often. Maybe once a day, once an hour, which will look like a wireless vibration sensor (Wireless vibration sensor) installed at the job site and can view the data through a computer. Suitable for areas that are difficult to reach and are highly dangerous. or want to keep more value

“Online” collects values in Realtime every second, suitable for very important machines. It is a wired sensor (Wireless vibration sensor) attached to the work site and can view data through a computer.Therefore, we should choose the equipment that best suits our needs for the greatest value in use.

FAADTECH : has vibration measurement equipment available in both Offline (Falcon), Semi-Online (Eagle), Online (MVX) to thoroughly meet all customer needs.

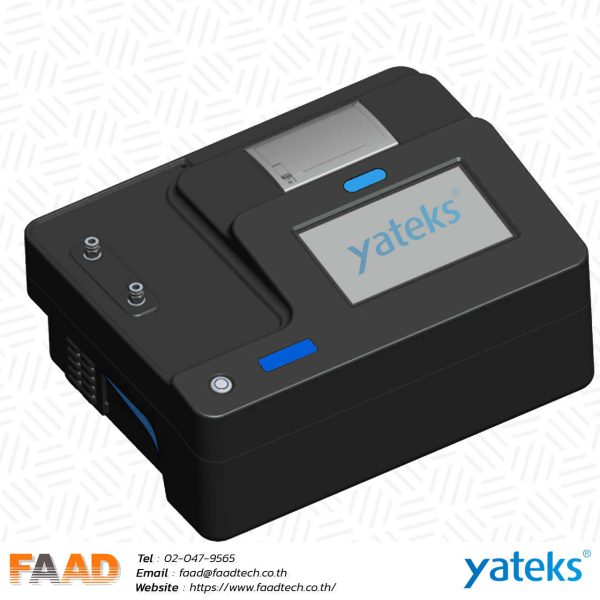

Oil And Lubrication Solutions

CMT’s oil test kit range offers lubricated machine operators a quick and easy way to self-check their machines at an affordable price. Oil test kits allow you to use the oil test results you get in minutes to make decisions about repairing a particular machine. It helps to confirm whether this critical machine will continue to operate or whether repairs should be planned to prevent unwanted shutdowns. Use your knowledge of oil parameters to understand the condition of your equipment. Choose to use the oil test kit and the parameters you want to know. It can be used separately or together in a single test set.

Thermo Scan Infrared Camera

With the XC600, anything is possible – because it's all included.

With this thermal imaging system You will benefit from accurate real-time measurement with high resolution, 10x zoom, fast autofocus with laser accuracy, built-in distance measurement functions, interval shooting, IR video and many measurement functions The XC600 thermal imaging camera is equipped with a high-capacity Li-ion battery for ultra long measurements. Can be used continuously and comes ready for use in a hard case. Includes high-quality analysis software

It can measure temperatures up to +600 °C (up to +1,500 °C with accessories). It is able to visualize temperature differences to a resolution of 0.05 °C (50 mK).

In addition to the laser distance measuring device Standard equipment of this thermal imaging camera also includes a conventional 5 megapixel camera and imaging light. Includes laser pointer for targeting What's more, the XC300 is Trotec's first thermal imaging camera to feature a high-capacity Li-ion battery, ensuring extended continuous use.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.

![[ASH456] – HIGH TEMP ACCELEROMETER [ASH456] – HIGH TEMP ACCELEROMETER](https://www.faadtech.co.th/wp-content/uploads/2024/07/dASH456-2-600x600.jpg.webp)