LEARN THE MOBIUS WAY

CONDITION MONITORING TRAINING AND CERTIFICATION

Master the knowledge and techniques to see the future

An organization with skilled condition monitoring technicians and analysts experiences lower maintenance costs and higher plant reliability. Condition monitoring allows us to detect the onset of failure and detect when the conditions exist that will cause future failures. Coupled with an effective planning and scheduling process, maintenance costs and production downtime can be dramatically reduced.

Rotating machinery, electrical equipment, and practically every other type of equipment you may operate in your plant provide an indication when failure is initiated, for example, when the bearing has the smallest crack forming. While it is necessary to understand how equipment fails, as a general comment, we can achieve anywhere from weeks, months, and even years of warning before failure occurs. That enables us to establish a corrective maintenance plan and schedule the work at the optimal time in order to reduce spare parts holding costs, the time required to perform the corrective maintenance, and the impact on production. Avoiding catastrophic failure obviously reduces the safety and environmental risks, and the possibility of secondary damage. Proper planning increases the quality of the work performed and reduces safety risks for the person performing the work.

It takes skill and dedication

But it takes a skilled group of technicians and analysts to conduct the right tests, at the right time, and correctly diagnose the problem and assess the severity. And it takes a skilled leader to manage the condition monitoring program to ensure everyone is trained and certified and the program is established correctly.

Mobius™ has the growth path to master condition monitoring

Mobius Institute™, and its worldwide authorized partners, provide training that equips technicians, analysts, and CBM leaders with the necessary skills so they can competently and confidently perform their critical roles.

Understanding how the equipment works, how they fail, how the symptoms of failure change over time, and how to correctly take the required measurements, requires detailed knowledge of the equipment and the instrumentation. Mobius Institute takes pride in the fact that we are recognized as the leaders in this form of training. We provide simulations that explain how the machinery and instrumentation work, and animations that enable you to visualize exactly what is going on.

No guesswork, no trying to remember complex concepts and techniques, we educate you so that you understand. It’s only when you understand that you can solve problems.

VIBRATION ANALYSIS TRAINING

VCAT-I VIBRATION ANALYSIS CATEGORY I

This is the place to start your vibration analysis career. You will learn all of the essentials so that you can contribute to the vibration analysis program:

▶ An introduction to condition monitoring and reliability improvement

▶ The fundamentals of vibration

▶ How to collect quality data

▶ An introduction to vibration analysis and common fault conditions

After this course, vibration analysis will make much more sense. You will learn how to do a good job and why it is so important that you do a good job.

The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

VCAT-II VIBRATION ANALYSIS CATEGORY II

This course will prepare you to be a real vibration analyst. You will learn:

▶ Vibration Measurement basics: sensors, mounting, locations, and collecting quality data

▶ Signal processing basics: sampling, windowing, averaging, and how to set up the data collected correctly

▶ Equipment fault conditions: unbalance, misalignment, bearings, resonance, and many more

▶ Vibration analysis techniques: spectral analysis, phase analysis, time waveform analysis

And you will learn many more tips, tricks, and concepts to help you succeed as a vibration analyst.

The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

VCAT-III VIBRATION ANALYSIS CATEGORY III

This course is for the leader of the vibration analysis program and the person who wants to be the vibration specialist. On this course you will learn:

▶ Advanced signal processing

▶ How to diagnose the widest range of fault conditions

▶ How to utilize all of the vibration data types

▶ Resonance, dynamics, modal, and ODS

▶ How to manage a program and lead the team

Every Vibration program should have a Category III vibration analyst leading the program. This is your chance to be the leader.

The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

VCAT-IV VIBRATION ANALYSIS CATEGORY IV

We call the vibration Category IV the “Vibration superheroes”. You have reached the pinnacle of the field. This course is challenging, but when you are up to it, the Mobius Institute™ course is the best way to be prepared to pass the exam. You will learn so much, but it is summarized below:

▶ Advanced signal processing

▶ Modal analysis and operating deflection shape analysis

▶ Machine and structural dynamics

▶ All of the measurement types associated with critical fluid film bearings

▶ How flexible rotor and fluid film bearing machines work

▶ Rotordynamics and flexible rotor balancing

And that is just the beginning. Our animations and simulations make it much easier to understand.

The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

Bearing Defender It takes only 10 seconds to collect, process and display the measured values in all three axes. The bearing’s full vibration readings are further shown on the information page.

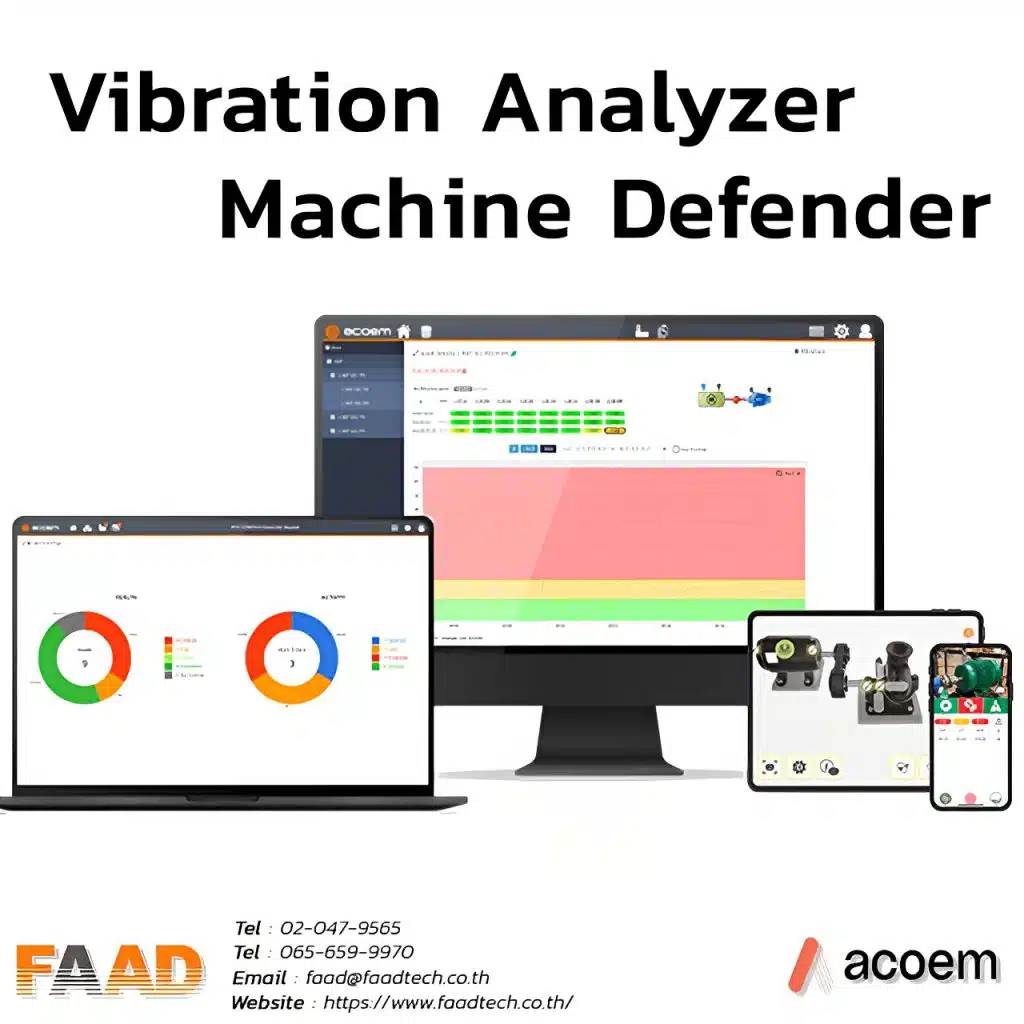

Vibration analyzer MD : It is an automatic vibration analysis tool. Data is delivered to your tablet in seconds with Acoem’s proprietary AI, delivering fast, relevant results.

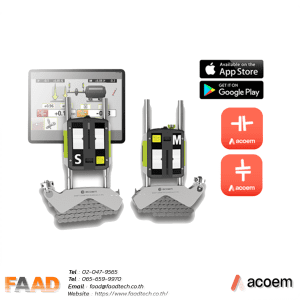

SMC : Able to check the condition of the rotary shaft machine as needed within a few minutes, both Vibration and Balance

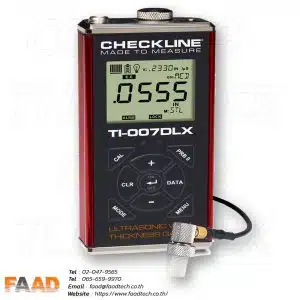

Falcon : ESSENTIAL is a vibration tool that is easy to use and has applications to help it work.

Read Our Latest News

News & Articles

- By Admin Faadtech

- Comments are off for this post.

- By Admin Faadtech

- Comments are off for this post.